EP0843149A1 - Composite armor panel and manufacturing method therefor - Google Patents

Composite armor panel and manufacturing method therefor Download PDFInfo

- Publication number

- EP0843149A1 EP0843149A1 EP96308166A EP96308166A EP0843149A1 EP 0843149 A1 EP0843149 A1 EP 0843149A1 EP 96308166 A EP96308166 A EP 96308166A EP 96308166 A EP96308166 A EP 96308166A EP 0843149 A1 EP0843149 A1 EP 0843149A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pellets

- panel

- mould

- composite armor

- armor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41H—ARMOUR; ARMOURED TURRETS; ARMOURED OR ARMED VEHICLES; MEANS OF ATTACK OR DEFENCE, e.g. CAMOUFLAGE, IN GENERAL

- F41H5/00—Armour; Armour plates

- F41H5/02—Plate construction

- F41H5/04—Plate construction composed of more than one layer

- F41H5/0414—Layered armour containing ceramic material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41H—ARMOUR; ARMOURED TURRETS; ARMOURED OR ARMED VEHICLES; MEANS OF ATTACK OR DEFENCE, e.g. CAMOUFLAGE, IN GENERAL

- F41H5/00—Armour; Armour plates

- F41H5/02—Plate construction

- F41H5/04—Plate construction composed of more than one layer

- F41H5/0492—Layered armour containing hard elements, e.g. plates, spheres, rods, separated from each other, the elements being connected to a further flexible layer or being embedded in a plastics or an elastomer matrix

Definitions

- the present invention relates to a composite armor panel. More particularly, the invention provides an armored panel providing lightweight ballistic protection which may be worn by the user, and for protecting light mobile equipment and vehicles against high-speed fire-arm projectiles or fragments. The invention also includes methods for manufacturing the panel.

- the first consideration is weight.

- Protective armor for heavy but mobile military equipment such as tanks and large ships, is known.

- Such armor usually comprises a thick layer of alloy steel, which is intended to provide protection against heavy and explosive projectiles. Due to its weight, such armor is quite unsuitable for light vehicles such as automobiles, jeeps, light boats, or aircraft, whose performance is compromised by steel panels having a thickness of more than a few millimeters.

- Armor for light vehicles is expected to prevent penetration of bullets of any weight, even when impacting at a speed in the range of 700 to 1000 meters per second.

- the maximum armor weight which is acceptable for use on light vehicles varies with the type of vehicle, but generally falls in the range of 40 to 70 kg/m 2 .

- a second consideration is cost. Overly complex armor arrangements, particularly those depending entirely on synthetic fibers, can be responsible for a notable proportion of the total vehicle cost, and can make its manufacture non-profitable.

- a third consideration in armor design is compactness.

- a thick armor panel including air spaces between its various layers, increases the target profile and the wind resistance of the vehicle.

- Ceramic materials are nonmetallic, inorganic solids having a crystalline or glassy structure, and have many useful physical properties, including resistance to heat, abrasion and compression, high rigidity, low weight in comparison with steel, and outstanding chemical stabiity. Such properties have long drawn the attention of armor designers, and solid ceramic plates, in thicknesses ranging from 3 mm. for personal protection to 50 mm. for heavy military vehicles, are commercially available for such use.

- a known form of armor plating using ceramics is produced in Israel by Kibbutz Beit Alpha. It comprises cutting 5 mm. steel plates to the sizes required, heat-treating the steel and adding a ceramic coating.

- One disadvantage of this type of panel is that on completion the panels are almost impossible to modify. In use, the ceramic coating performs well against the first bullet, but tends to shatter, and thus fails to protect against further projectiles.

- a common problem with prior art ceramic armor concerns damage inflicted on the armor structure by a first projectile, whether stopped or penetrating. Such damage weakens the armor panel, and so allows penetration of a following projectile, impacting within a few centimeters of the first.

- the present invention is therefore intended to obviate the disadvantages of prior art ceramic armor, and to provide an armor panel which is effective against small-caliber fire-arm projectiles, yet is of light weight, i.e, having a weight of less than 45 kg/m 2 , which is equivalent to about 9 lbs/ft 2 , and low bulk.

- a further object of the invention is to provide an armor panel which is particularly effective in arresting a plurality of projectiles impacting upon the same general area of the panel.

- a composite armor material for absorbing and dissipating kinetic energy from high velocity, armor-piercing projectiles comprising a panel consisting essentially of a single internal layer of high density ceramic pellets having an Al 2 0 3 content of at least 85% and a specific gravity of at least 2.5, said pellets being directly bound and retained in panel form by a solidified material which is elastic at a temperature below 250°C, the majority of said pellets each having a major axis in the range of about 3-12 mm, and being bound by said solidified material in a plurality of superposed rows, wherein a majority of each of said pellets is in contact with at least 4 adjacent pellets, and the total weight of said panel does not exceed 45 kg/m 2 .

- Said solidified material can be any suitable material, such as molten metal which is elastic at a temperature below 250°C, such as aluminum, epoxy, a thermoplastic polymer, or a thermoset plastic.

- an armored panel wherein the solidified material contains at least 80% aluminum.

- the elasticity of the material used in the present invention serves, to a certain extent, to increase the probability that a projectile will simultaneously impact several pellets, thereby increasing the efficiency of the stopping power of the panel of the present invention.

- a multi-layered armor panel comprising an outer, impact-receiving panel of composite armor material as hereinbefore defined, for deforming and shattering an impacting high velocity, armor-piercing projectile; and an inner layer adjacent to said outer panel, comprising second layer comprising a panel of tough woven textile material for causing an asymmetric deformation of the remaining fragments of said projectile and for absorbing the remaining kenetic energy from said fragments, said inner layer having a thickness of at least 50% of that of said outer, impact-receiving panel, wherein said panel is adapted to stop three bullets fired seqentially at a triangular area of said panel, the sides of said triangle being 5 cm each.

- composite armor plate comprising a mass of spherical ceramic balls distributed in an aluminum alloy matrix is known in the prior art.

- prior art composite armor plate suffers from one or more serious disadvantages, making it difficult to manufacture and less than entirely suitable for the purpose of defeating metal projectiles.

- McDougal, et al. U.S. Patent 3,705,558 discloses a lightweight armor plate comprising a layer of ceramic balls.

- the ceramic balls are in contact with each other and leave small gaps for entry of molten metal.

- the ceramic balls are encased in a stainless steel wire screen; and in another embodiment, the composite armor is manufactured by adhering nickel-coated alumina spheres to an aluminum alloy plate by means of a polysulfide adhesive.

- Composite armor plate as described in the McDougal, et al. patent is difficult to manufacture because the ceramic spheres may be damaged by thermal shock arising from molten metal contact. The ceramic spheres are also sometimes displaced during casting of molten metal into interstices between the spheres.

- Huet U.S. Patents 4,534,266 and 4,945,814 propose a network of interlinked metal shells to encase ceramic inserts during casting of molten metal. After the metal solidifies, the metal shells are incorporated into the composite armor. It has been determined, however, that such a network of interlinked metal shells substantially increases the overall weight of the armored panel and decreases the stopping power thereof.

- McDougal suggests and teaches an array of ceramic balls disposed in contacting pyrimidal relationship, which arrangement also substantially increases the overall weight of the armored panel and decreases the stopping power thereof, due to a billiard-like effect upon impact.

- the novel armor of the present invention traps incoming projectiles between several sphere-like, very hard ceramic pellets which are held in a single layer in rigid mutual relationship.

- the moderate size of the pellets ensures that the damage caused by a first projectile is localized and does not spread to adjoining areas.

- An incoming projectile may contact the pellet array in one of three ways:

- the present invention provides a method for producing a composite armor material as defined hereinabove, comprising providing a mould having a bottom, two major surfaces, two minor surfaces and an open top, wherein the distance between said two major surfaces is from about 1.2 to about 1.8 times the major axis of said pellets; inserting said pellets into said mould to form a plurality of superposed rows of pellets extending substantially along the entire distance between said minor side surfaces, and from said bottom substantially to said open top; incrementally heating said mould and the pellets contained therein to a temperature of at least 100°C above the flow point of the material to be poured in the mould; pouring molten material into said mould to fill the same; allowing said molten material to solidify; and removing said composite armor material from said mould.

- the present invention also provides a method for producing a composite armor material, comprising providing a mould having a bottom, two major surfaces, two minor surfaces and an open top, wherein the distance between said two major surfaces is from about 1.2 to 1.8 times the major axis of said pellets; inserting said pellets into said mould to form a plurality of superposed rows of pellets extending substantially along the entire distance between said minor side surfaces, and from said bottom substantially to said open top; pouring liquid epoxy resin into said mould to fill the same; allowing said epoxy to solidify; and removing said composite armor material from said mould.

- said pellets do not necessarily have to be completely covered on both sides by said solidified material, and they can touch or even bulge from the outer surfaces of the formed panel.

- a panel 14 is formed from a solidified material 16, the panel having an internal layer of high-density ceramic pellets 18.

- the outer faces of the panel are formed from the solidified material 16, and pellets 18 are embedded therein.

- the nature of the solidified material 16 is selected in accordance with the weight, performance and cost considerations applicable to the intended use of the armor.

- Armor for land and sea vehicles is suitably made using a metal casting alloy containing at least 80% aluminum.

- a suitable alloy is Aluminum Association No. 535.0, which combines a high tensile strength of 35,000 kg/in 2 , with excellent ductility, having 9% elongation.

- Further suitable alloys are of the type containing 5% silicon B443.0. These alloys are easy to cast in thin sections; their poor machinability is of little concern in the application of the present invention.

- An epoxy or other plastic or polymeric material, advantageously fiber-reinforced, is also suitable.

- Pellets 18 have an alumina (Al 2 O 3 ) content of at least 93%, and have a hardness of 9 on the Mohs scale. Regarding size, the majority of pellets have a major axis in the range of from about 3-12 mm, the preferred range being from 6-10 mm.

- Fig. 1 There are shown in Fig. 1, for illustrative purposes, a mixture of round pellets 18a, flat-cylindrical pellets 18b, and spherical pellets 18c. Considerations of symmetry, as well as tests carried out by the present inventor, indicate that the most effective pellet shape is spherical 18c. Ceramic pellets are used as grinding media in size-reduction mills of various types, typically in tumbling mills, and are thus commercially available at a reasonable cost.

- pellets 18 are bound by the solidified molten material 16 in a plurality of superimposed rows 20. A majority of pellets 18 are each in contact with at least 4 adjacent pellets.

- the panel 14 acts to stop an incoming projectile 12 in one of three modes: centre contact, flank contact, and valley contact, as described above.

- a pellet 18d having a regular, geometric, prismatic form, with one convex curved surface segment 22.

- Fig. 3 shows a pellet 18e having a circular cross-section 24, taken at line AA.

- the pellet is of satellite form, and is commercially available.

- Fig. 4 illustrates a multi-layered, armor panel 26, having a configuration which is particularly suitable for armored clothing.

- similar identification numerals are used for identifying similar parts.

- An outer, impacting panel 28 of composite armor material is similar to panel 14 described above with reference to Fig. 1.

- Panel 28 acts to deform and shatter an impacting high velocity projectile 12.

- Light-weight armor for personal protection is made using a tough, yet hard, thermoplastic resin, for example, polycarbonate or acrylonite-butadiene-styrene.

- Inner panel layer 30 is adjacent to outer panel 28, and is advantageously attached thereto.

- Inner panel layer 30 has a thickness of at least 50% of that of outer impacting panel 28.

- Inner panel 30 is made of a tough woven material, such as multiple layers of Kevlar®, or a material known by its trade name of Famaston.

- inner layer panel 30 comprises multiple layers of a polyamide netting.

- inner panel 30 causes asymmetric deformation of the remaining fragments 32 of the projectile 12, and absorbs remaining kinetic energy from these fragments by deflecting and compressing them in the area 34 seen in Fig. 1. It is to be noted that area 34 is much larger than the projectile cross-section, thus reducing the pressure felt on the inner side 36 of inner panel 30. This factor is important in personally-worn armor.

- a casting mould 38 used for producing a composite armor material 10 as described above with reference to Fig. 1.

- the following elevated-temperature method of manufacture is used:

- Step A

- a mould 38 is provided, having a bottom 40, two major surfaces 42, two minor surfaces 44 and an open top 46, wherein the distance between these two major surfaces 42 is 1.2 to 1.8 times the major axis of the pellets 18. For example, 8 mm pellets are used and the distance between major surfaces is 10 mm.

- Step B

- Pellets 18 are inserted into mould 38 to form a plurality of superposed rows 20 of pellets 18, extending substantially along the entire distance between the minor side surfaces 44, and from the bottom 40 substantially to the open top 46.

- Step C

- Mould 38 and the pellets 18 contained therein are incrementally heated, first to a temperature of about 100°C, and then further heated to a temperature of at least 100°C above the flow point of the material to be poured in the mould.

- a temperature of about 100°C For example, aluminium has a flow point of about 540°C, and will require heating the mould, together with ceramic pellets contained therein, to above 640°C.

- Step D

- Molten material 16 is poured into mould 38 to fill the same.

- a typical pour temperature range for aluminium is 830-900°C.

- Polycarbonate is poured at between 250-350°C.

- the surfaces of mould 38 are provided with a plurality of air holes 48, to facilitate the escape of air while molten material 16 is poured therein.

- the pellets 18 are slightly rearranged in accordance with the hydrostatic and hydrodynamic forces exerted upon them by the molten material.

- Step E

- Molten material 16 is allowed to solidify.

- Step F

- Composite armor material 10 is removed from mould 38.

- the following embodiment of a method of manufacture includes the use of an epoxy resin to form a themoset matrix.

- an epoxy resin to form a themoset matrix.

- epoxies can be cast at room temperature and chemically hardened, or their hardening can be accelerated by the application of heat.

- Epoxy armor is suitable for use on aircraft. Yield strength and Young's modulus are both improved by adding fiber reinforcement.

- Step A

- Mould 38 is provided, having a bottom 40, two major surfaces 42, two minor surfaces 44 and an open top 46, wherein the distance between the two major surfaces 42 is from about 1.2 to 1.8 times the major axis of the pellets 18.

- Step B

- Pellets 18 are inserted into mould 38 to form a plurality of superposed rows 20 of pellets 18 extending substantially along the entire distance between the minor side surfaces 44, and from the bottom 40 substantially to the open top 46.

- Step C

- Liquid epoxy resin is poured into mould 38 to fill the same.

- Step D

- the epoxy is allowed to solidify.

- Step E

- the composite armor material is removed from mould 38.

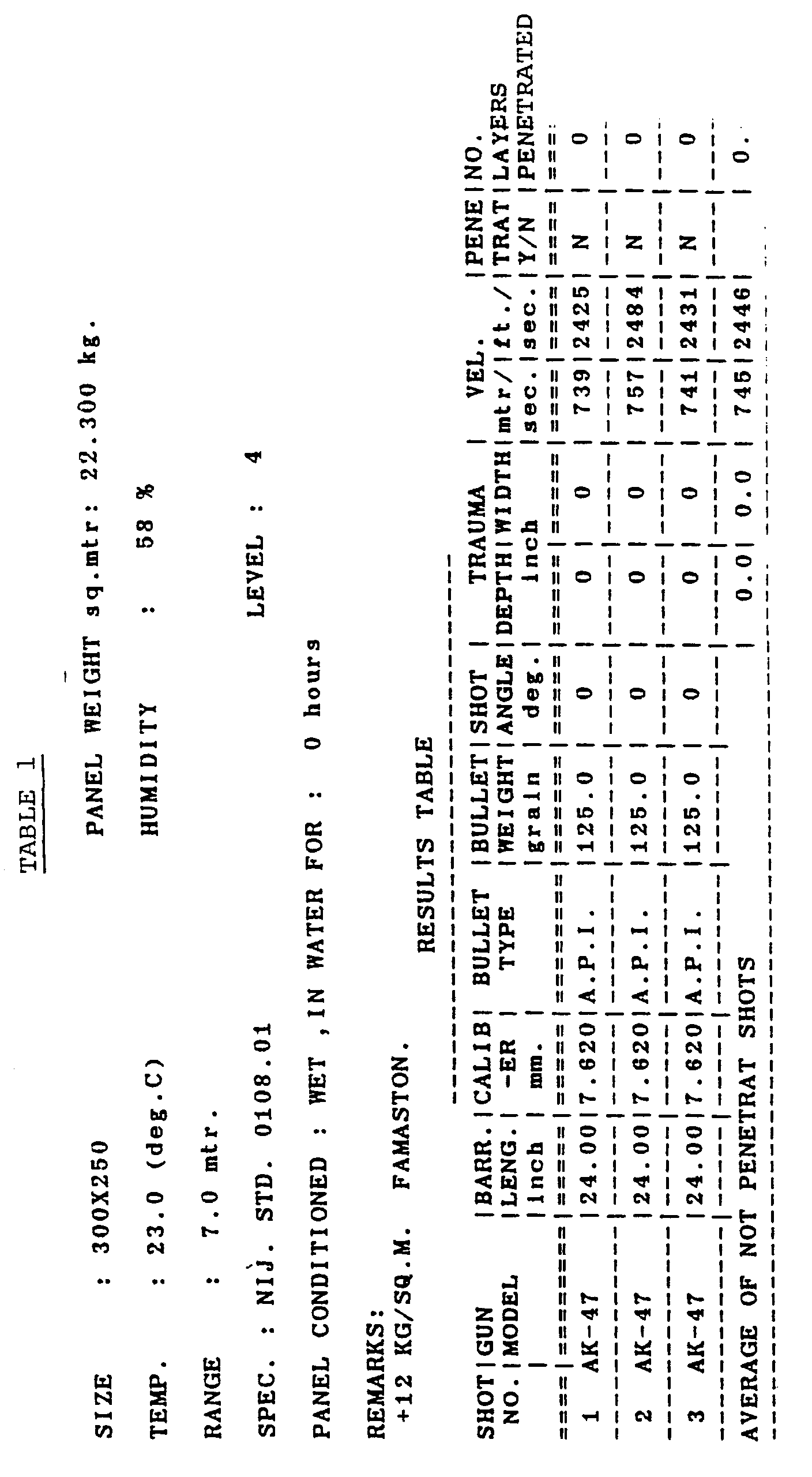

- Table 1 is a reproduction of a test report relating to the aluminium matrix multi-layer panel described above with reference to Fig. 4. Three armor-piercing bullets were fired at close range from an AK-47 assault rifle at a multi-layered panel having a total weight of 34.3 kg/m 2 , a weight low enough for limited use as personally worn armor. The results reported prove the effectiveness of the panel manufactured according to the present invention.

Abstract

Description

- Fig. 1

- is a perspective, fragmented view of a preferred embodiment of an armor panel according to the invention;

- Figs. 2 and 3

- are perspective views of further pellet embodiments;

- Fig. 4

- is a sectional view of a two-layer embodiment of the armor panel; and

- Fig. 5

- is a diagrammatic view of a mould used in the methods for manufacturing the panel.

Claims (17)

- A composite armor material for absorbing and dissipating kinetic energy from high velocity, armor-piercing projectiles, comprising:a panel consisting essentially of a single internal layer of high density ceramic pellets having an Al203 content of at least 85% and a specific gravity of at least 2.5, said pellets being directly bound and retained in panel form by a solidified material which is elastic at a temperature below 250°C;the majority of said pellets each having a major axis in the range of about 3-12 mm, and being bound by said solidified material in a plurality of superposed rows;

wherein a majority of each of said pellets is in contact with at least 4 adjacent pellets, and the total weight of said panel does not exceed 45 kg/m2. - A composite armor material as claimed in claim 1, wherein the majority of said pellets each has a major axis in the range of from about 6 to about 10 mm.

- A composite armor material as claimed in claim 1, wherein said pellets are of a regular geometric form, having at least one convex curved surface segment.

- A composite armor material as claimed in claim 1, wherein said pellets have at least one circular cross- section.

- A composite armor material as claimed in claim 1, wherein said pellets are of round, flat-cylindrical or spherical shape.

- A composite armor material as claimed in claim 1, wherein said ceramic pellets have an Al2O3 content of at least 90% and a specific gravity of at least 3.

- A composite armor material as claimed in claim 1, wherein said pellets have an A1203 content of at least 93%, and have a hardness of 9 on the Mohs scale.

- A composite armor material as claimed in claim 1, wherein said solidified material contains at least 80% aluminium.

- A composite armor material as claimed in claim 1, wherein said solidified material is a thermoplastic resin.

- A composite armor material as claimed in claim 1, wherein said solidified material is an epoxy.

- A multi-layered armor panel, comprising:an outer, impact-receiving panel of composite armor material according to claim 1, for deforming and shattering an impacting high velocity, armor-piercing projectile; andan inner layer adjacent to said outer panel, comprising second layer comprising a panel of tough woven textile material for causing an asymmetric deformation of the remaining fragments of said projectile and for absorbing the remaining kenetic energy from said fragments;said inner layer having a thickness of at least 50% of that of said outer, impact-receiving panel;

wherein said panel is adapted to stop three bullets fired seqentially at a triangular area of said panel, the sides of said triangle being 5 cm each. - A multi-layered, armor panel according to claim 11, wherein said second panel is made of Kevlar®.

- A multi-layered, armor panel according to claim 11, wherein said inner layer comprises multiple layers of a polyamide netting.

- A method for producing a composite armor material according to claim 1, comprising:providing a mould having a bottom, two major surfaces, two minor side surfaces and a open top, wherein the distance between said two major surfaces is from about 1.2 to 1.8 times the major axis of said pellets;inserting said pellets into said mould to form a plurality of superposed rows of pellets extending substantially along the entire distance between said minor side surfaces, and from said bottom substantially to said open top;incrementally heating said mould and the pellets contained therein to a temperature of at least 100°C above the flow point of the material to be poured in the mould;pouring said molten material into said mould to fill the same;allowing said molten material to solidify; andremoving said composite armor material from said mould.

- A method as claimed in claim 14, wherein said solidified molten material comprises a casting alloy containing at least 80% aluminium, and said mould is heated to a temperature of at least 850°C.

- A method as claimed in claim 14, wherein said surfaces of said mould are provided with a plurality of air holes to facilitate the escape of air while said molten material is poured therein.

- A method according to claim 14 for producing a composite armor material, comprising:providing a mould having a bottom, two major surfaces, two minor surfaces and an open top, wherein the distance between said two major surfaces is from about 1.2 to 1.8 times the major axis of said pellets;inserting said pellets into said mould to form a plurality of superposed rows of pellets extending substantially along the entire distance between said minor side surfaces, and from said bottom substantially to said open top;pouring liquid epoxy resin into said mould to fill the same;allowing said epoxy to solidify: andremoving said composite armor material from said mould.

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP96308166A EP0843149B1 (en) | 1996-11-12 | 1996-11-12 | Composite armor panel and manufacturing method therefor |

| ES96308166T ES2124067T3 (en) | 1996-11-12 | 1996-11-12 | COMPOSITE ARMORING PANEL AND ITS MANUFACTURING METHOD. |

| DK96308166T DK0843149T3 (en) | 1996-11-12 | 1996-11-12 | Composite armor plate and method for making such |

| DE69600574T DE69600574T2 (en) | 1996-11-12 | 1996-11-12 | Composite armor plate and manufacturing method |

| AT96308166T ATE170285T1 (en) | 1996-11-12 | 1996-11-12 | COMPOSITE ARMOR PLATE AND METHOD FOR PRODUCTION |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP96308166A EP0843149B1 (en) | 1996-11-12 | 1996-11-12 | Composite armor panel and manufacturing method therefor |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0843149A1 true EP0843149A1 (en) | 1998-05-20 |

| EP0843149B1 EP0843149B1 (en) | 1998-08-26 |

Family

ID=8225148

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96308166A Revoked EP0843149B1 (en) | 1996-11-12 | 1996-11-12 | Composite armor panel and manufacturing method therefor |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0843149B1 (en) |

| AT (1) | ATE170285T1 (en) |

| DE (1) | DE69600574T2 (en) |

| DK (1) | DK0843149T3 (en) |

| ES (1) | ES2124067T3 (en) |

Cited By (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1999050612A1 (en) * | 1998-03-30 | 1999-10-07 | Mofet Etzion | Composite armor panel |

| WO1999053260A1 (en) * | 1998-04-14 | 1999-10-21 | Michael Cohen | Composite armor panel |

| EP0959321A1 (en) | 1998-05-19 | 1999-11-24 | Michael Cohen | Composite armour plate |

| EP1166031A1 (en) | 1999-02-09 | 2002-01-02 | Rafael - Armament Development Authority Ltd. | Ballistic armor panel |

| WO2002029351A1 (en) | 2000-10-05 | 2002-04-11 | Michael Cohen | Composite armor panel |

| US6624106B2 (en) * | 2000-05-02 | 2003-09-23 | Michael Cohen | Alumina ceramic products |

| EP0942255B1 (en) * | 1998-03-10 | 2006-08-16 | Mofet Etzion | Composite armor panel |

| US7117780B2 (en) | 2003-08-26 | 2006-10-10 | Michael Cohen | Composite armor plate |

| EP1737653A2 (en) * | 2004-04-23 | 2007-01-03 | The United States of America as Represented by The Secretary of The Navy | Armor including a strain rate hardening elastomer |

| US7383762B2 (en) | 2005-04-03 | 2008-06-10 | Michael Cohen | Ceramic pellets and composite armor panel containing the same |

| US7543523B2 (en) | 2001-10-01 | 2009-06-09 | Lockheed Martin Corporation | Antiballistic armor |

| EP2071272A2 (en) | 2007-12-11 | 2009-06-17 | Michael Cohen | Composite armor plate and method for using the same |

| US7603939B2 (en) | 2003-10-02 | 2009-10-20 | Michael Cohen | Ceramic bodies for armor panel |

| EP2146178A2 (en) * | 2008-07-17 | 2010-01-20 | Plasan Sasa Ltd | Armour panel |

| EP2426454A2 (en) | 2010-09-07 | 2012-03-07 | Michael Cohen | High density ceramic bodies and composite armor comprising the same |

| RU2462682C2 (en) * | 2010-09-07 | 2012-09-27 | Майкл КОЭН | High density ceramic blocks and composite armor comprising them |

| US8281700B2 (en) | 2004-09-08 | 2012-10-09 | Michael Cohen | Composite armor plate and ceramic bodies for use therein |

| US8833229B2 (en) | 2005-03-30 | 2014-09-16 | The Secretary Of State For Defence | Ceramic armour element for use in armour |

| RU2539269C1 (en) * | 2013-06-13 | 2015-01-20 | Закрытое акционерное общество "Научно-производственное объединение специальных материалов" | Volume-combined armour |

| RU2542813C1 (en) * | 2013-11-19 | 2015-02-27 | Открытое акционерное общество "Обнинское научно-производственное предприятие "Технология" | Volumetric combination armour |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005013660A1 (en) | 2005-03-24 | 2006-09-28 | Krauss-Maffei Wegmann Gmbh & Co. Kg | Composite armor plate for protecting vehicles or buildings from armor-piercing projectiles with high kinetic energy |

| ATE503981T1 (en) | 2007-02-14 | 2011-04-15 | Krauss Maffei Wegmann Gmbh & C | METHOD FOR PRODUCING A COMPOSITE ARMOR PLATE |

| EP2023072A1 (en) | 2007-08-09 | 2009-02-11 | ETEC Gesellschaft für technische Keramik mbH | Set of pellets for armor protection |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1081464A (en) * | 1963-08-06 | 1967-08-31 | Feldmuehle Ag | Armour plate |

| FR1566448A (en) * | 1967-03-01 | 1969-05-09 | ||

| US3705558A (en) * | 1963-04-24 | 1972-12-12 | Gen Motors Corp | Armor |

| GB1352418A (en) * | 1971-05-11 | 1974-05-08 | Feldmuehle Anlagen Prod | Armour plate |

| US4061815A (en) * | 1967-10-26 | 1977-12-06 | The Upjohn Company | Novel compositions |

| FR2559254A1 (en) * | 1984-02-02 | 1985-08-09 | Picard | Armour resistant to piercing and process for producing it. |

| DE3228264A1 (en) * | 1981-08-13 | 1985-12-05 | Harry 7311 Hochdorf Apprich | Bulletproof multi-layer material |

| DE3507216A1 (en) * | 1985-03-01 | 1986-09-04 | Rheinmetall GmbH, 4000 Düsseldorf | Composite plate |

| GB2272272A (en) * | 1992-11-10 | 1994-05-11 | T & N Technology Ltd | Armour |

| US5361678A (en) * | 1989-09-21 | 1994-11-08 | Aluminum Company Of America | Coated ceramic bodies in composite armor |

| FR2711782A1 (en) * | 1991-07-30 | 1995-05-05 | Creusot Loire | Armour element comprising a system of particles made of hard material, and method of making this armour element |

-

1996

- 1996-11-12 AT AT96308166T patent/ATE170285T1/en not_active IP Right Cessation

- 1996-11-12 EP EP96308166A patent/EP0843149B1/en not_active Revoked

- 1996-11-12 ES ES96308166T patent/ES2124067T3/en not_active Expired - Lifetime

- 1996-11-12 DE DE69600574T patent/DE69600574T2/en not_active Revoked

- 1996-11-12 DK DK96308166T patent/DK0843149T3/en active

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3705558A (en) * | 1963-04-24 | 1972-12-12 | Gen Motors Corp | Armor |

| GB1081464A (en) * | 1963-08-06 | 1967-08-31 | Feldmuehle Ag | Armour plate |

| FR1566448A (en) * | 1967-03-01 | 1969-05-09 | ||

| US4061815A (en) * | 1967-10-26 | 1977-12-06 | The Upjohn Company | Novel compositions |

| GB1352418A (en) * | 1971-05-11 | 1974-05-08 | Feldmuehle Anlagen Prod | Armour plate |

| DE3228264A1 (en) * | 1981-08-13 | 1985-12-05 | Harry 7311 Hochdorf Apprich | Bulletproof multi-layer material |

| FR2559254A1 (en) * | 1984-02-02 | 1985-08-09 | Picard | Armour resistant to piercing and process for producing it. |

| DE3507216A1 (en) * | 1985-03-01 | 1986-09-04 | Rheinmetall GmbH, 4000 Düsseldorf | Composite plate |

| US5361678A (en) * | 1989-09-21 | 1994-11-08 | Aluminum Company Of America | Coated ceramic bodies in composite armor |

| FR2711782A1 (en) * | 1991-07-30 | 1995-05-05 | Creusot Loire | Armour element comprising a system of particles made of hard material, and method of making this armour element |

| GB2272272A (en) * | 1992-11-10 | 1994-05-11 | T & N Technology Ltd | Armour |

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0942255B1 (en) * | 1998-03-10 | 2006-08-16 | Mofet Etzion | Composite armor panel |

| WO1999050612A1 (en) * | 1998-03-30 | 1999-10-07 | Mofet Etzion | Composite armor panel |

| WO1999053260A1 (en) * | 1998-04-14 | 1999-10-21 | Michael Cohen | Composite armor panel |

| EP0959321A1 (en) | 1998-05-19 | 1999-11-24 | Michael Cohen | Composite armour plate |

| WO1999060327A1 (en) * | 1998-05-19 | 1999-11-25 | Michael Cohen | Composite armor plate |

| EP1166031A1 (en) | 1999-02-09 | 2002-01-02 | Rafael - Armament Development Authority Ltd. | Ballistic armor panel |

| US6624106B2 (en) * | 2000-05-02 | 2003-09-23 | Michael Cohen | Alumina ceramic products |

| WO2002029351A1 (en) | 2000-10-05 | 2002-04-11 | Michael Cohen | Composite armor panel |

| US7543523B2 (en) | 2001-10-01 | 2009-06-09 | Lockheed Martin Corporation | Antiballistic armor |

| US7117780B2 (en) | 2003-08-26 | 2006-10-10 | Michael Cohen | Composite armor plate |

| US7603939B2 (en) | 2003-10-02 | 2009-10-20 | Michael Cohen | Ceramic bodies for armor panel |

| EP1737653A2 (en) * | 2004-04-23 | 2007-01-03 | The United States of America as Represented by The Secretary of The Navy | Armor including a strain rate hardening elastomer |

| EP1737653A4 (en) * | 2004-04-23 | 2009-04-01 | Us Navy | Armor including a strain rate hardening elastomer |

| US8281700B2 (en) | 2004-09-08 | 2012-10-09 | Michael Cohen | Composite armor plate and ceramic bodies for use therein |

| US8833229B2 (en) | 2005-03-30 | 2014-09-16 | The Secretary Of State For Defence | Ceramic armour element for use in armour |

| US7383762B2 (en) | 2005-04-03 | 2008-06-10 | Michael Cohen | Ceramic pellets and composite armor panel containing the same |

| EP2071272A2 (en) | 2007-12-11 | 2009-06-17 | Michael Cohen | Composite armor plate and method for using the same |

| EP2146178A2 (en) * | 2008-07-17 | 2010-01-20 | Plasan Sasa Ltd | Armour panel |

| EP2146178A3 (en) * | 2008-07-17 | 2012-10-17 | Plasan Sasa Ltd | Armour panel |

| EP2426454A2 (en) | 2010-09-07 | 2012-03-07 | Michael Cohen | High density ceramic bodies and composite armor comprising the same |

| RU2462682C2 (en) * | 2010-09-07 | 2012-09-27 | Майкл КОЭН | High density ceramic blocks and composite armor comprising them |

| US8438963B2 (en) | 2010-09-07 | 2013-05-14 | Michael Cohen | High density ceramic bodies and composite armor comprising the same |

| RU2539269C1 (en) * | 2013-06-13 | 2015-01-20 | Закрытое акционерное общество "Научно-производственное объединение специальных материалов" | Volume-combined armour |

| RU2542813C1 (en) * | 2013-11-19 | 2015-02-27 | Открытое акционерное общество "Обнинское научно-производственное предприятие "Технология" | Volumetric combination armour |

Also Published As

| Publication number | Publication date |

|---|---|

| DK0843149T3 (en) | 1999-05-25 |

| EP0843149B1 (en) | 1998-08-26 |

| ES2124067T3 (en) | 1999-01-16 |

| DE69600574D1 (en) | 1998-10-01 |

| DE69600574T2 (en) | 1999-06-17 |

| ATE170285T1 (en) | 1998-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5763813A (en) | Composite armor panel | |

| US6112635A (en) | Composite armor panel | |

| EP1071916B1 (en) | Composite armor panel | |

| EP0843149B1 (en) | Composite armor panel and manufacturing method therefor | |

| US6289781B1 (en) | Composite armor plates and panel | |

| US6575075B2 (en) | Composite armor panel | |

| US7117780B2 (en) | Composite armor plate | |

| EP0929788B2 (en) | Ceramic bodies for use in composite armor | |

| US7603939B2 (en) | Ceramic bodies for armor panel | |

| CA2309053C (en) | Composite armor panel | |

| US20070028757A1 (en) | Composite armor plate and ceramic bodies for use therein | |

| US20090241764A1 (en) | Composite Armor Plate and Ceramic Bodies for Use Therein | |

| EP0942255B1 (en) | Composite armor panel | |

| CA2331529C (en) | Composite armor plate | |

| CA2206262C (en) | Composite armor panel | |

| AU743578B2 (en) | Composite armor panel | |

| NZ504079A (en) | Composite Armor Panel with high density ceramic pellets in rows bound and retained in plate form, ceramic pellets have an alumina content of at least 93% and at least one axis of 3mm in length |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19970212 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| REF | Corresponds to: |

Ref document number: 170285 Country of ref document: AT Date of ref document: 19980915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 69600574 Country of ref document: DE Date of ref document: 19981001 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: TROESCH SCHEIDEGGER WERNER AG |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2124067 Country of ref document: ES Kind code of ref document: T3 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19981119 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| 26 | Opposition filed |

Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA Effective date: 19990507 |

|

| 26 | Opposition filed |

Opponent name: ETEC GESELLSCHAFT FUER TECHNISCHE KERAMIK MBH Effective date: 19990521 Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA Effective date: 19990507 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: ETEC GESELLSCHAFT FUERTECHNISCHE KERAMIK MBH Effective date: 19990521 Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA Effective date: 19990507 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| R26 | Opposition filed (corrected) |

Opponent name: ETEC GESELLSCHAFT FUERTECHNISCHE KERAMIK MBH Effective date: 19990521 Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA Effective date: 19990507 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: ETEC GESELLSCHAFT FUER TECHNISCHE KERAMIK MBH Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| APAA | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOS REFN |

|

| R26 | Opposition filed (corrected) |

Opponent name: ETEC GESELLSCHAFT FUERTECHNISCHE KERAMIK MBH Effective date: 19990521 Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA Effective date: 19990507 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: ETEC GESELLSCHAFT FUER TECHNISCHE KERAMIK MBH Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: ETEC GESELLSCHAFT FUER TECHNISCHE KERAMIK MBH Effective date: 19990521 Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA Effective date: 19990507 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: ETEC GESELLSCHAFT FUER TECHNISCHE KERAMIK MBH Opponent name: RAFAEL ARMAMENT DEVELOPMENT AUTHORITY/ PLASAN-SASA |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20071104 Year of fee payment: 12 Ref country code: MC Payment date: 20071026 Year of fee payment: 12 Ref country code: LU Payment date: 20071114 Year of fee payment: 12 Ref country code: ES Payment date: 20071219 Year of fee payment: 12 Ref country code: DK Payment date: 20071115 Year of fee payment: 12 Ref country code: DE Payment date: 20071108 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MP4A Effective date: 20080123 |

|

| 27W | Patent revoked |

Effective date: 20071115 |

|

| GBPR | Gb: patent revoked under art. 102 of the ep convention designating the uk as contracting state |

Free format text: 20071115 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20071114 Year of fee payment: 12 Ref country code: AT Payment date: 20071113 Year of fee payment: 12 Ref country code: FI Payment date: 20071114 Year of fee payment: 12 Ref country code: IT Payment date: 20071123 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20071106 Year of fee payment: 12 |

|

| NLR2 | Nl: decision of opposition |

Effective date: 20071115 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: ECNC |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20071107 Year of fee payment: 12 Ref country code: FR Payment date: 20071108 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20071025 Year of fee payment: 12 Ref country code: GR Payment date: 20071030 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080131 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20071113 Year of fee payment: 12 |